Low-VOC collision repair is a game-changer in the automotive industry, prioritizing safety and health by reducing volatile organic compounds (VOCs) in paint and solvents. This technology offers improved indoor air quality, superior durability, a wide color range, and benefits for dent and fender repairs, making it a top choice for high-quality results while fostering eco-friendliness and safer work environments.

Low-VOC (volatile organic compound) collision repair is transforming industry standards, prioritizing shop safety and employee well-being. This innovative approach replaces harmful chemicals with safer alternatives, significantly reducing toxic fumes and enhancing air quality. By understanding the benefits of low-VOC paint and implementing safe work practices, shops can create a healthier environment for their employees while meeting stringent environmental regulations. Discover how this revolutionary method is redefining collision repair standards and ensuring a brighter, safer future for all involved.

- Understanding Low-VOC Paint and Its Benefits

- Implementing Safe Work Practices in Collision Repair

- Enhancing Air Quality for Shop Employees

Understanding Low-VOC Paint and Its Benefits

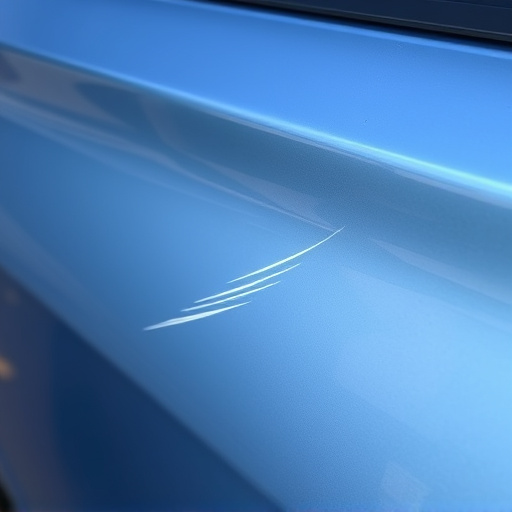

Low-VOC (volatile organic compound) paint is a game-changer in the automotive industry, especially for collision repair shops. This type of paint offers numerous benefits, making it a preferred choice for professionals dedicated to maintaining high safety standards. By reducing the release of harmful gases and chemicals, low-VOC paints significantly improve air quality within repair facilities. This is particularly crucial for shop employees, many of whom spend long hours in these spaces, minimizing exposure to potentially toxic substances is essential.

Moreover, low-VOC collision repair provides a healthier environment not only for workers but also for customers visiting auto repair shops near me. The reduced odor and lower emissions contribute to better air ventilation, ensuring a more comfortable experience. In addition, these paints often offer excellent durability and a wide range of colors, allowing for high-quality repairs on various vehicle surfaces, be it dent repair or fender repair.

Implementing Safe Work Practices in Collision Repair

In the realm of auto collision centers, prioritizing safety is paramount. Low-VOC collision repair plays a pivotal role in fostering safer work environments by minimizing exposure to harmful volatile organic compounds (VOCs). These substances, often found in traditional paints and solvents, can pose significant health risks to technicians and other shop personnel. By adopting low-VOC practices, auto collision centers significantly reduce the risk of respiratory issues, skin irritation, and other health problems associated with prolonged contact with toxic chemicals.

Implementing safe work practices in auto repair services extends beyond chemical management. It involves a comprehensive approach that includes proper training for staff, adherence to safety protocols, and ensuring adequate ventilation systems are in place. These measures collectively contribute to creating a healthier, more productive environment for everyone involved, making low-VOC collision repair not just an eco-friendly choice but also a sensible one from a workplace safety perspective.

Enhancing Air Quality for Shop Employees

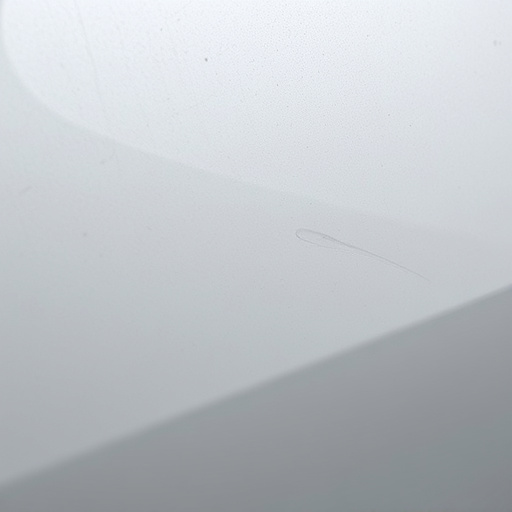

In auto body shops, where collisions are routinely repaired, air quality is a significant concern for employee health and safety. Traditional collision repair processes often involve the use of harmful chemicals and paints that release volatile organic compounds (VOCs) into the air. These VOCs can cause respiratory issues, skin irritation, and other health problems for workers who are repeatedly exposed to them. Low-VOC collision repair offers a significant advantage by reducing these emissions, creating a healthier work environment. By using low-VOC or VOC-free products, including paints and adhesives, auto body shops can minimize the release of noxious fumes, ensuring better air quality for their employees.

This shift towards low-VOC collision repair is particularly beneficial for workers involved in bumper repair and other car bodywork services. It helps maintain a clean, safe space for them to perform their tasks without worrying about acute or chronic health effects associated with high VOC exposure. As the demand for eco-friendly solutions grows, adopting low-VOC practices not only enhances shop safety standards but also positions auto body shops as forward-thinking and responsible businesses.

Low-VOC collision repair isn’t just an eco-friendly choice; it’s a critical step towards enhancing shop safety standards. By understanding and implementing these practices, collision repair shops can improve air quality, protect employees from harmful fumes, and contribute to a healthier work environment. This approach not only benefits workers’ well-being but also aligns with the growing demand for sustainable and safe automotive services.