The EPA has implemented strict guidelines to limit VOC emissions from vehicle paint repair and collision shops, focusing on low-VOC collision repair. To meet these standards, professionals adopt low-VOC paints with lower chemical content, reducing air pollution and improving workplace safety for employees vulnerable to high VOC exposure. This shift promotes sustainable practices in the automotive industry through faster drying times, reduced odours, and better durability, while also ensuring adherence to EPA regulations through proper ventilation systems and regular tool cleaning.

In the realm of automotive restoration, adhering to environmental regulations is paramount. Low-VOC (volatile organic compound) collision repair emerges as a game-changer, aligning perfectly with EPA guidelines on VOC emissions. This article delves into the intricacies of these guidelines and explores how low-VOC paints and materials are revolutionizing collision repair practices. We’ll uncover best strategies to ensure compliance, fostering both environmental stewardship and high-quality repairs.

- Understanding EPA Guidelines on VOC Emissions

- The Role of Low-VOC Paints and Materials in Collision Repair

- Best Practices for Ensuring Compliance During the Repair Process

Understanding EPA Guidelines on VOC Emissions

The Environmental Protection Agency (EPA) has set strict guidelines regarding Volatile Organic Compound (VOC) emissions, especially in the automotive industry, to combat air pollution and its detrimental effects on human health and the environment. These guidelines are particularly relevant in the context of vehicle paint repair and automotive collision repair shops. The EPA defines VOCs as chemicals that easily evaporate at room temperature, contributing to smog formation and ozone pollution.

Low-VOC collision repair is a crucial approach adopted by many automotive professionals to meet these stringent regulations. By using paints and coatings with lower VOC content, collision repair shops can significantly reduce the release of harmful substances into the atmosphere during the vehicle paint repair process. This not only helps in minimizing environmental impact but also ensures safer working conditions for employees in these workshops, as exposure to high VOC levels can be hazardous.

The Role of Low-VOC Paints and Materials in Collision Repair

In the realm of low-VOC collision repair, the use of low-volatile organic compound (low-VOC) paints and materials plays a pivotal role in adhering to Environmental Protection Agency (EPA) guidelines. These innovative products are designed to significantly reduce the emission of harmful chemicals during auto painting and vehicle bodywork processes, contributing to cleaner air quality both within repair shops and the surrounding environment. By adopting low-VOC options for car dent repair, professionals can substantially decrease the risk of health issues associated with traditional paints, making their workplaces safer.

Moreover, the shift towards low-VOC collision repair isn’t just an environmental imperative; it’s a step toward enhancing workplace safety and promoting sustainable practices in the automotive industry. These advanced materials not only comply with stringent EPA regulations but also offer advantages such as faster drying times, reduced odours, and better durability, thereby streamlining the entire car dent repair process. This approach ensures that collision repair services can be delivered efficiently while upholding ecological stewardship.

Best Practices for Ensuring Compliance During the Repair Process

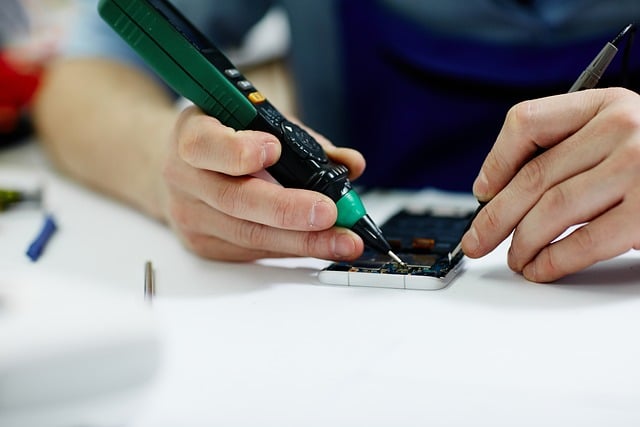

Ensuring compliance with EPA guidelines during low-VOC collision repair involves adhering to best practices that safeguard both the environment and the well-being of technicians. The first step is utilizing low-emitting paints and materials, which significantly reduce volatile organic compound (VOC) emissions. These products not only meet regulatory standards but also create a healthier workspace for body shop services professionals.

Additionally, proper ventilation systems play a crucial role in car collision repair processes. Adequate extraction of VOCs from the work area through high-efficiency filters ensures that technicians are protected from inhaling harmful chemicals. Regular cleaning and maintenance of tools and equipment used in vehicle repair services further contribute to minimizing environmental impact and maintaining compliance standards.

Low-VOC collision repair is not just a trend but a necessary practice to adhere to EPA guidelines and promote environmental sustainability. By adopting low-VOC paints and materials, along with best practices during the repair process, shops can effectively reduce volatile organic compound (VOC) emissions. This approach ensures a healthier work environment for technicians while contributing to better air quality. Embracing these measures is a step towards a greener future for the automotive industry, where every collision repair counts as a significant contribution to environmental preservation.